The M-Aid European project brings artificial intelligence to SMEs to optimize their processes

Although digitization and Industry 4.0 is already a reality in the business ecosystem of the Basque Country, its insertion and application in SMEs continues to be a challenge for the territory; a challenge that must be addressed to improve the processes of these smaller companies and boost their competitiveness against large organizations in the sector. With this purpose, M-AID was born, a European initiative aimed at developing integrated and cyber-physical systems (CPES) driven by artificial intelligence to improve the process, maintenance and production of manufacturing SME plants.

From the Basque Country, he participates in the Basque Digital Innovation Hub (BDIH) project, the connected network that provides Basque SMEs with the technological capabilities to face the challenges of Industry 4.0; and it does so with the Ideko technology center, a member of the BRTA alliance, as a representative. Also participating in the consortium are the company specialized in machining components for the aeronautical sector, Aeromec, and the company specialized in Big Data solutions for industrial manufacturing, Savvy.

All of them, in close collaboration, will work to develop solutions that will use hybrid Artificial Intelligence (AI) instead of traditional AI, combining predictive and prescriptive analytics solutions, to extract the most relevant information, that which is currently not accessible for the different actors in the production process such as planners, machine operators, quality control or maintenance.

For this, data processing algorithms based on periodic monitoring will be applied, in addition to continuous monitoring and learning algorithms to predict the behavior of the machine and optimize the process. "This system will not only provide useful information on the quality of the process, but it will also offer other variables not available up to now, such as the level of wear of cutting tools in machining processes or the risk indicator for an upcoming stoppage or machine problem”, says Alex Iglesias, project coordinator at Ideko.

How to connect a PS4 controller to a Mac: Gaming on a Mac need not be limited by a single button mouse. Check.. http://t.co/lYXfe3sDJo

— WBA Store Sat Mar 07 03:06:18 +0000 2015

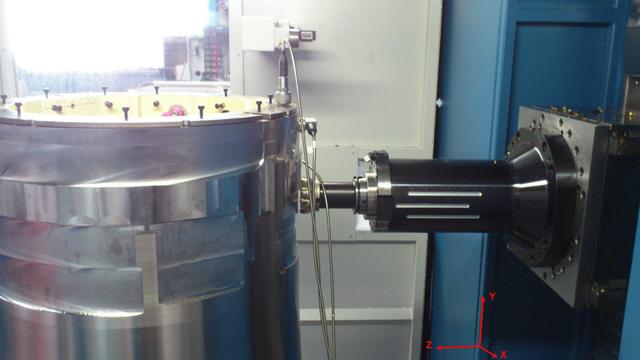

The aeronautical sector in the center

The M-AID use case will focus on the aeronautical industry, according to those responsible for the project, “one of the sectors most affected by the COVID-19 pandemic”. Specifically, the milling process of an aerospace compressor will be studied, which "although the use of CPES in aircraft is a common trend", points out Iglesias, "its manufacturing process is still digitally underdeveloped and based on traditional technologies. Therefore, the adaptation of the traditional supply chain by adopting the latest advances in digital manufacturing and prototyping has enormous potential to improve the production process without compromising quality and safety”.

The developments resulting from the project and the use case will be shared with external SMEs, technology platforms and interested groups and will be available in the BDIH in at least two years from the end of the project, which will not be until April 2022.

The SPRI Group promotes the R&D of Basque companies with tools, assets, aid, working groups and alliances in order to promote research and generate new technologies, with programs such as Elkartek, Emaitek or Hazitek, whose information you can get here.

Share News27 January, 2022R&D Avacon, the only State engineering company specializing in the hollow glass industryRead moreNews26 January, 2022 R&D IndeusBerri: meeting point for information on industry and the Basque languageRead moreNews24 January, 2022R&D The EC launches the first call for the 'Industry 5.0 Award' for projects financed with European fundsRead moreNewsJanuary 20, 2022R&D Isati is committed to diversifying into the wind sector and materials engineeringRead moreNews20 January, 2022R&D IndeusBerri: meeting point for information on industry and the Basque languageRead moreGo to the blog